Sustainability within Profeeds and Nutrimaster

Profeeds and Nutrimaster

Profeeds is a leading Zimbabwean stock feed manufacturer who produces feed for poultry (both broilers and layers), cattle, pig, goat, rabbit, horse, fish feed as well as dog food.

The company distributes its feed through 47 retail stores nationwide. The shops provide a complete agri-solution for Zimbabwe farmers for stock feed, veterinary products, farming equipment, farming implements, seed, fertiliser and other agri inputs as well as provide training on product use.

Nutrimaster uses latest technology to ensure effective blending of fertilisers whilst integrating all aspects of social responsibility into the design of the plant. Strategies to implement training and correct use of the product to both small-scale and commercial farmers to improve their agricultural yields are a key objective.

Key Sustainability Highlights

- Profeeds upgraded its production facility in 2022 by installing a new and efficient pelleting machine. A second boiler was also successfully installed to enable smooth planned maintenance without interference on production flow. A new and efficient hammer mill is being installed which will improve production efficiency and reduce occupational dust exposure.

- A new water-cooling system for the extruder at Aquafeeds was installed.

- Profeeds has developed and successfully implemented a waste management plan whereby all major waste streams generated are separated and recycled or reused.

- Profeeds installed supplementary solar power at shops around the country to reduce pressure on the national grid.

Key Sustainability Highlights (continued)

- Profeeds installed Power Factor Correction (PFC) measures to significantly improve performance and maintenance of plant facilities. These improvements include:

- Prolonging the life of electrical equipment

- Increasing effective capacity of the local electricity network, with the potential to defer future investment in electrical infrastructure

- Reducing unscheduled production downtime and associated losses and maintenance costs

- Improving product quality and decreasing product reject rates

- Reducing energy losses as equipment will run at lower temperatures

- Avoiding voltage drops over long cables and reducing efficiency losses in ZESA supply transformers

- Reducing poor power factor, which causes losses of transformers and other devices and machines, leading to inefficiency and unwanted heat gains that, in turn, result in premature equipment failure and production losses. Businesses with poor power factor also incur a ‘poor power factor penalty’ from ZESA, otherwise known as a reactive power charge

Community Involvement

- Profeeds and Nutrimaster continued to provide technical training on animal health to small scale farmers to empower and help communities on cleaning and disinfection, to its client base of small-scale farmers as well as commercial growers.

- Profeeds introduced ‘Meet the Expert’ days where Profeeds technical specialists sit in one of its shops and customers come with their various topics for discussions.

- Nutrimaster sponsored the “Moms are Geniuses” initiative by donating fertiliser to help support rural women farmers.

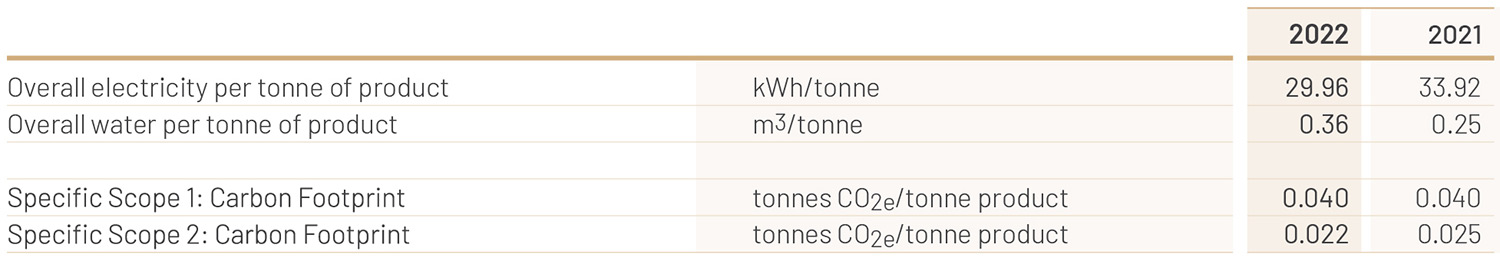

Key annual environmental data for Profeeds